Photopolymer Plates For Letterpress

We currently stock two guages of polymer plates and will soon be stocking a steel backed material as well as producing rubber stamps. Currently available is a standard .95mm plate (KF95) and the much sought after 1.52mm deep relief plate (KF152).

You can order undeveloped KF95 and KF152 plates from us to use on your own equipment or hand processing, we can also process plates for you from your artwork and post them to you the same day. We do need your order and artwork by mid-day to guarantee same day dispatch, but even if your order & artwork arrives later we will try to get it out the same day if we can.

These plates have a shore hardness of 67 which makes them perfect for deep impression work which is so popular today – Toyobo (the manufacturer) produce these plates specifically for letterpress work. They’re durable for quite long press runs if cured properly and can be used time after time, just clean them well (we recommend a diluted water miscibile press wash then dry well with a soft cloth and leave to air dry overnight) and store them in a ziplock bag and preferably in a dark place, a draw or filing cabinet is ideal. A full set of fact sheets can be downloaded form our manuals catalogue.

Correct Developing For Good Letterpress

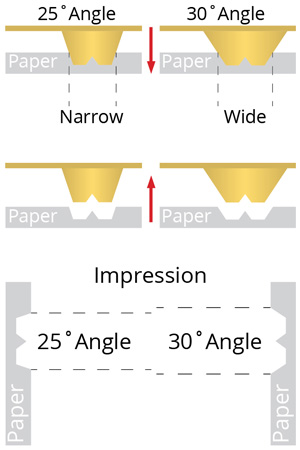

We can send a .pdf product data sheet to new customers which can be helpful to those working with unexposed materials. If you’re developing your own plates – whether using expensive equipment like ours or home made UV units and a hairdryer – should remember that times used for exposure and drying are intrisic to the properties of the finished plate. A developed plate has a shoulder which slopes outward from the imaged surface.

If this shoulder is too narrow, even though your impression is deep it is still not easy to see the letterpress effect. We’ve been shown deep steel backed plates which have virtually no shoulder and the work produced using them although deep was not noticeable. If you want letterpress that ‘pop’s’ and that you can see at a glance (usually indicated by a white glow) then we can help. I should point out that this is not traditional letterpress which is a gentle kiss to the paper but it is what’s so popular now in the latest development of this craft as an artform.

Here’s the key, the shoulder should be between 25° – 30° then the letterpress effect is more obvious. You’ll have to play with this depepnding on your equipment and process but exposing the plates to UV light for the right amount of time governs the angle of the shoulder though times vary for plate type and process. For those of you buying developed plates from us we take care of this and provide plates that give good results for deep letterpress (regardless of which plate thickness you choose).

If you have special requirements or concerns just call us, and don’t forget we can send a small sample plate so you know what you’re getting. Use the contact form to request this service, it’s free!

Plate Processing

Photopolymer plates work by exposure to UV light through film negatives (it’s crucial for commercial work to have a vacuum sealed unit to press the film to the plate or you may get poor results) which imposes the image and makes the polymer ‘cure’ whilst the unexposed area can be washed away.

It is vital therefore to protect plates pre and post exposure from UV light.

Washing the plates after exposure is done via light brushing in clean warm water apporximately 20-25°C (68-77°F) and takes around five minutes for manually or three to four minutes mechanically. Brushes must be soft to avoid damaging the plates which require drying with warm air and a second exposure in the UV unit to cure the plates.

Main Exposure is between three minutes thirty and five minutes thirty. Hot air drying takes approximately ten minutes at 60-70°C (140-158°F) – nice in the winter! Post exposure in the UV unit takes about another ten to twenty minutes depending on main exposure time.