Polymer Stamps a Rubber Equivalent!

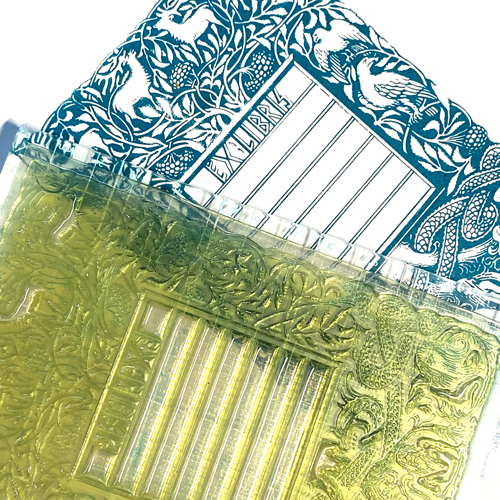

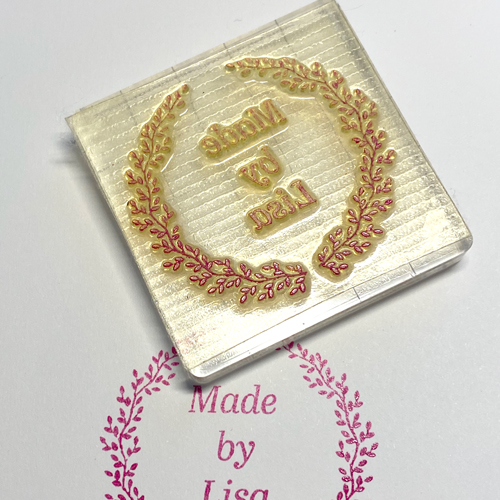

Our polymer stamps are made using the same process that we use to make our letterpress printing plates but we use a softer grade polymer, they give you a lovely clean image and being clear you can see where you’re placing them.

They come supplied with sticky mount on the back which means they are ready to use as soon as they are delivered, just mount on an acrylic block. Our polymer stamps are also flexible and easy to reposition, if you haven’t got it on your block right just peal it off and pop it down again.

You can easily produce easily create different colour overlays. If you already use stamps, you may have your own preferred method of mounting them, but we really do recommend acrylic mounting blocks, just stick down the stamp and off you go. The acrylic blocks are also available in our store.

You may just need a logo stamp making, or a stamp for wedding envelopes, maybe just a return address. Maybe you use them for something craftier, our polymer stamps are more than capable of handling all the above.

Our polymer stamps are a similar price to our standard letterpress printing plates, far from expensive and we price on the total size of the artwork supplied, not by individual stamp. If you’d like a price, just send your artwork over and we’ll have a look. If you order more than one plate on a sheet, you’ll only need a pair of scissors to separate them.

The process to making as environmentally friendly as it can be, no chemicals here and we recycle all that we can throughout the process.

Just like our letterpress printing plates our photopolymer stamps can be turned around in under 24hours. We send out a neg proof in the same way, prior to invoicing, we then invoice and upon payment we will make your stamp.

Ink Compatibility, we’ve played and so far, we haven’t broken a stamp. We’ve tried dye and pigment inks as well as our letterpress printing inks. We’ve noticed some of the dye inks may stain but they do not affect the actual printing of the stamp.

They are tough and flexible, and they don’t go out of shape. The base of the plate is made from the same polyester that is on our foil backed plates and before we send them out, we pop on sticky mount, so they are ready to attach to the acrylic blocks, when you’re finished, just peal them off.

So, how long do they last? Well, we haven’t broken one yet and we’ve been trying. If they are cleaned and stored correctly you should be able to keep coming back to them again and again, unless they’ve been ordered for a single purpose. Looking after your stamps is down to you, if you have a design that has some fine areas, you will have to be careful that you’re not too rough when using them, but they are quite forgiving. We recommend storing the stamps at room temperature and in something like a grip-seal bag, just like our polymer letterpress plates.

Our polymer stamps are thicker than our letterpress printing plates as well as being softer. They are 1.70mm which gives a deep enough relief and holds the finer details, just like our standard printing plates, they will hold a min. line thickness of 0.35pt, that’s fine!

Email your artwork to plates@lymebaypress.com, the same guidelines for producing the artwork apply to the polymer plates as the standard letterpress plates. We’ll check it over and send you back a neg proof and a price.

Because of how they are made, we can make you a single stamp or many on a single sheet, up to A3 in size. How small or how large you need depends on your own designs. A3 is the largest our machines can handle; you can have more than one piece of artwork on a plate of stamps.

So, why use polymer stamps, apart from all the above…

Well, firstly, they cost a lot less than rubber stamps and they are quicker to have made. They take up a lot less space than mounted rubber stamps, just keep a selection of acrylic blocks to mount them on.

Depending on the size of your order the stamps will be posted first class, cheaper than a small parcel for a wooden handle.

Cleaning is easy, we’ve tried them with soap and water, press wash and white spirit, it all depends on the type of ink you’re using.

So, what are you waiting for, give them a go.