KF152 Letterpress Printing Plates are commonly used in Letterpress printing due to the several advantages they offer:

- High Quality: KF152 plates provide excellent print quality with fine details and smooth tones. They have a good ability to reproduce intricate designs accurately, making them suitable for various printing applications.

- Durability: These plates are known for their durability and resistance to wear and tear. They can withstand long print runs without deteriorating in quality, which makes them cost-effective for bulk printing jobs.

- Consistency: KF152 plates offer consistent results over multiple print runs. They maintain their dimensional stability, ensuring that the printed output remains consistent without variations in color or registration.

- Versatility: They can be used for printing on a variety of substrates, including paper, cardboard, film, and various types of packaging materials. This versatility makes them a popular choice across different industries.

- Ease of Use: KF152 plates are relatively easy to handle and process, allowing for faster setup times. This convenience can contribute to increased productivity in printing operations.

- Environmental Friendliness: Compared to some other printing plates, KF152 plates are considered to be more environmentally friendly due to their reduced use of solvents and chemicals in the plate-making process.

- Cost-effectiveness: Their durability and consistent performance make them cost-effective in the long run, especially for large-scale printing jobs.

The Toyobo KF152 letterpress printing plates are a specific type of photopolymer printing plates designed for letterpress printing. Toyobo is a well-known manufacturer of photopolymer plates and other printing-related materials.

Here are some key characteristics and information about Toyobo KF152 letterpress printing plates:

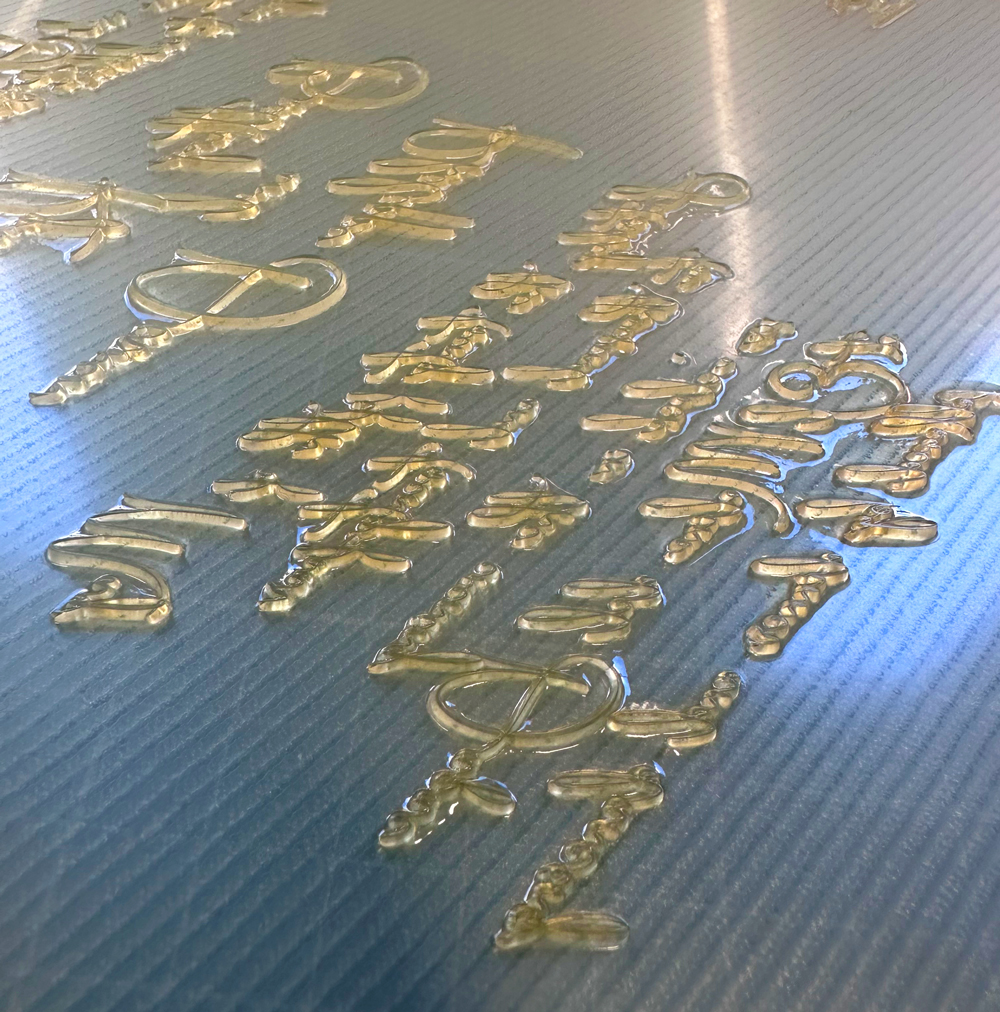

- Material: Toyobo KF152 plates are made from a photosensitive polymer material. This material is sensitive to UV light and undergoes a chemical change when exposed to UV light, allowing for the creation of raised printing surfaces.

- Applications: These plates are primarily designed for letterpress printing, which is a relief printing process where the raised portions of the plate transfer ink onto paper or other surfaces. Letterpress is often used for high-quality printing applications such as business cards, invitations, packaging, and specialty labels.

- Resolution: Toyobo KF152 plates are capable of holding fine details and intricate designs, making them suitable for various printing projects that require precise and high-quality results.

- Plate Thickness: These plates come in various thicknesses to accommodate different printing needs and equipment. The choice of plate thickness can affect the depth of impression and overall print quality.

- Plate Sizes: Toyobo KF152 plates are available in different sizes to fit various letterpress printing presses and specific project requirements.

- Exposure: To create the printing surface on Toyobo KF152 plates, a digital design or image is typically printed onto a transparent film or digital negative. This film is then used to expose the plate to UV light. The areas exposed to UV light harden, while the unexposed areas remain soft and can be washed away during plate development.

- Plate Development: After exposure, the plate is developed to remove the unexposed polymer, leaving behind the raised image or text that will be used for printing.

- Printing: Once the plate is mounted on the letterpress, ink is applied to the raised surface of the plate, and the press transfers the ink onto the printing surface, creating the printed image or text with a tactile quality.

Toyobo KF152 letterpress printing plates are known for their quality and versatility in the letterpress printing industry. Printers often choose these plates when they need to achieve precise and visually appealing results in their letterpress projects.

We have been using and supplying KF152 Letterpress Printing Plates now for several years, both in our plate making business and printing. Combined with our Chase Base or mounted type high, to 0.918in, they are a wonderful addition to any letterpress studio. There is no alternative to the KF152 plate, pretenders to the throne offer a deeper plate but our letterpress polymer plates have a shore hardness of 67 and are suitable for many thousands of impressions. Recommended for a deep relief the KF152 has a steeper neck than the KF95 and give that beautiful deep impression that many clients want to see from letterpress printing. They can hold a fine line, down to 0.35pt and work really well on all board thicknesses but show up really well on anything over 300gsm. We’ve used them successfully on a 1050gsm triplex board before now to great effect.

Post Exposed Plates (Imaged & Ready To Run)

If you would like to order post-exposed plates (imaged from your art-work) then you can calculate prices using the price calculator then email plates@lymebaypress.com with your artwork, where we will send you back a neg proof, once approved we go ahead and make your letterpress polymer plate. We have hundreds of clients who use out letterpress printing plates and keep coming back for more. If you would like to try a samples of both of our polymer printing plates please drop us a line at plates@lymebaypress.com with your address and we’ll pop some in the post to you.

Unexposed Plates (Raw Polymer Plate)

If you want to order raw unexposed materials to process yourself then you can do that here. We offer various pack sizes to try and make this as viable as possible for any body wanting to bring more of their print process under their control. Both thicknesses of plates are available from our online store and we also supply then to Silverclay jewellery makers and sign makers, just to show how adaptable they are. You will need specialist equipment in order to process your own plates and we can offer help in getting this, just drop us a line. Click here to go over to our store…