Type High Blocks — Type-High Letterpress Blocks by Lyme Bay Press

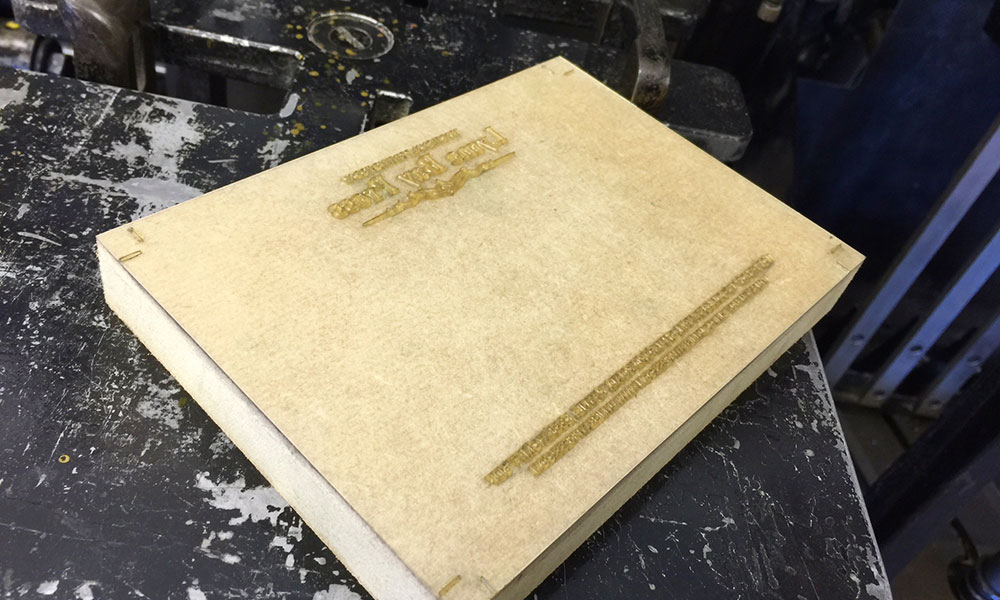

At Lyme Bay Press, we now offer type high blocks designed to integrate photopolymer relief printing with traditional hand-set type. These precision-made blocks bring your imagery and non-standard fonts up to the type high standard (0.918 in / 23.32 mm), letting you lock them straight into your chase for seamless letterpress printing.

Whether you’re a classic press operator using handset type or a modern letterpress artist combining plates and movable type, our Type High Blocks expand your creative possibilities.

Why Use Type High Blocks in Your Letterpress Studio?

-

Seamless integration with metal type

These blocks are manufactured to exactly 0.918 in (23.32 mm) — the standard type high — ensuring they sit flush in the chase alongside handset type or cast metal. -

Used with KF152 polymer plates

Our type high blocks are engineered to accept Toyobo KF152 deep-relief photopolymer plates, letting you mount imagery or non-standard text directly onto the block and print in a single pass. -

Drop-in compatibility

Because they match the type high standard, they “drop into” your chase without shimwork or adjustment — speeding your setup and eliminating misregistration. -

Durable, water/chemical resistant material

Built from a special MDF board with treated surfaces, our blocks resist moisture, ink, and cleaning chemicals commonly used in the printshop. -

Expand your creative workflow

Ideal for printers wanting to mix handset type, ornaments, and photographic plates in one chase lock-up — perfect for wedding stationery, fine art prints, luxury invites, and bookwork.

Specifications & Options

| Feature | Detail |

|---|---|

| Height (type high) | 0.918 in / 23.32 mm |

| Plate compatibility | Designed for mounting KF152 photopolymer plates |

| Material & finish | Water- and chemical-resistant treated MDF |

| Lock-up method | Fits conventional chase — no extra shimming required |

| Use case | Combine handset type with plates, bespoke or image work |

You can mount your imagery or typography onto the block, lock it into your chase, and begin letterpress printing — no leveling, no re-shimming.

How to Use Type High Blocks in Your Press Workflow

-

Prepare your design / artwork

Ensure your artwork is suitable for relief printing and formatted with correct dimensions and bleed, per our artwork guidelines. -

Lock into chase and register

Place the block (with adhered plate) into your chase, align using the chase grid, and tighten your lock-up. -

Ink, test, and adjust

Ink your forme, pull test prints, check impression evenness, then run your full press job. -

Clean & reuse

After the run, carefully remove the polymer (if reusable), clean the block, and keep it ready for future projects.

Why Letterpress Printers in the UK Choose Our Type High Blocks

-

Local supply, fast UK delivery

We deliver across mainland UK, so your blocks arrive quickly without international delays. -

Designed by printers, for printers

Lyme Bay Press is a working letterpress studio — we understand the challenges of setup, registration, and make-ready. -

Engineered for compatibility

Works with common UK presses and chase systems, ideal for combining with our other offerings (plates, bases, ink supplies). -

Reliable and stable

The specially treated MDF construction resists moisture and chemical attack in real shop conditions.

Ordering & Support

-

Ordering— Just send us your artwork and we’ll look after everything for you

-

Custom sizes available — If you need a non-standard block size or custom cut, contact us.

-

Technical assistance — We offer help with artwork, mounting, registration, and beginner support. Just email info@lymebaypress.com