Letterpress Bronzing Powders

We have had a very positive response to the bronzing powders that we now sell through our store, we’ve struggled sometimes to keep them on the shelf but it’s good to know that people like and want them. We now have a full shelf full if you would like to order through the store… just click here

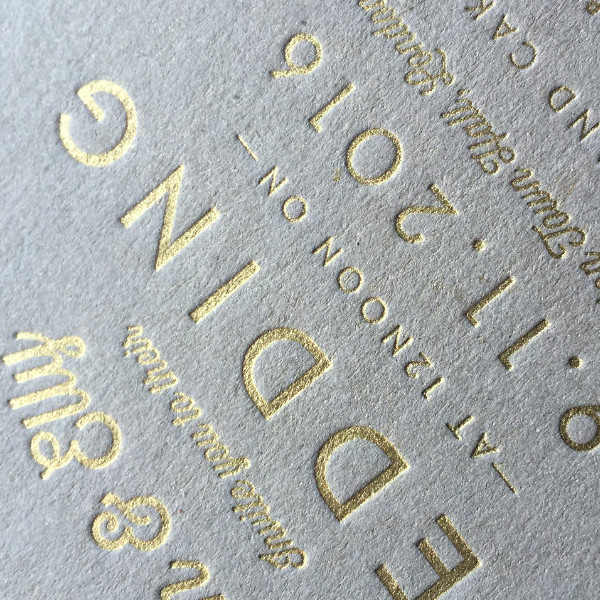

Not every letterpress printer has access to a hot foil machine or wants to. Instead you can use a very fine metallic bronzing powder to lift metallic ink which can sometimes look a little dark and flat on an uncoated board. When applied to a wet ink and then dusted off, you are left with a lovely sheen of shiny metal on top of your ink. Silver, Gold and Copper are now available through our store here. If you need any advice on how to use them please do get in touch. Just look how lovely they are in the little sample below…

Letterpress Bronzing – Adding the final touch

Letterpress Bronzing is a wonderful age old technique used to lift a print without moving into the foiling finish. It is a time consuming process and you have to allow time during printing to complete the bronzing process. Also enough room to make a mess is essential and you do have to take the correct safety precautions.

Safety First

Bronzing is a technique achieved by adding a very fine layer of a metallic powder on to wet ink. It is left to dry and then brushed off the finished print. Because of the nature of the material, we recommend using it in a well ventilated area, if you have extraction equipment, this should be used, we use a small extraction cupboard just to help us. We also recommend a face mask which covers both nose and mouth as well as goggles, not the swimming variety, but if you get stuck, these are better than nothing! And don’t forget to cover your clothing, the letterpress bronzing powders are finer than glitter and will get into all those places you didn’t think you had.

Let’s Bronze

Once you have your work area set up, lets print. You can still print letterpress with a reasonable amount of impression if that’s what your design requires. If you are printing with a gold ink, we recommend a gold bronzing powder, the same for silver and copper, but there is no reason you can’t mix and match. We’ve printed with a transparent ink in the past and applied the letterpress bronzing powder to that… and it works. In fact the bronzing powders will stick to anything, so be careful of any sticky fingerprint on your prints as it will stick to this too. The bronzing powders are also suitable for use with both oil based and rubber based inks.

We recommend taking only 10 impressions at a time, so that the ink remains tacky, when you’ve printed 10, take them to the work area you have set up for your bronzing and apply a generous amount of your chosen powder to the print and work it into the printed area using a softish paintbrush , be quite firm, but not too rough. Continue until you have completed the 10 printed that you have, knock off any loose powder, you can return it to the jar and go back and print another 10. Continue in this vein until you have printed and bronzed your work.

Finishing Up

When you’ve cleaned down your press, assuming that you’ve finished with it, you can return to the printed that you’ve applied the letterpress bronzing powder to. you will definitely need that mask and goggles now, using a firmer brush, clean down each print, you don’t have to do this straight away and can even leave the prints for a few ours to make sure that ink has gone off. You may have to go over your prints a couple of times but we’re sure you’ll be pleased with all of the effort that you’ve put into creating them.

Don’t forget you can always get in touch if you have any questions info@lymebaypress.com and if you’re itching to buy the letterpress bronzing powders, you’ll find them here on our store….